Our

mission

& Vision

Create income generation opportunities in rural areas using local resources and appropriate technology

We work on development of agro and food processing technology solutions which will improve constraints of traditional technologies and adopt features of modern technologies at a smaller scale and an affordable investment.

We are passionate technologists, strongly believing in “Small is Beautiful” philosophy of E. F. Schumacher for creating resource efficient appropriate technologies. These appropriate technologies are primarily in the domain of food and agro processing to empower people in rural and semi-urban areas for local wealth and employment creation. We have strong technology foundation with its roots in IIT Bombay, Oxford University UK, UICT, Mumbai and NCL, Pune along with more than four decades of industrial and research experience.

Alignment with UN SDG

Zero hunger

Gender Equality

Decent Work and

Economic Growth

Industry Innovation

and Infrastructure

Reduced Inequalities

Responsible Consumption

and Production

Zero hunger

End hunger, achieve food security and improved nutrition and promote sustainable agriculture. The SARVAAY jaggery technology provides opportunity to increase farmers income and provide micronutrient rich alternative for white sugar to the world.

Gender Equality

Aims to grant women and girls equal rights, opportunities to live free without discrimination including workplace discrimination or any violence. At SARVAAY jaggery processing plant is operated by more than 70% women staff leading to economic and social empowerment.

Decent Work and Economic Growth

aims at ensuring the economic sector of every country provides the necessary need for its citizen to have a good life irrespective of their background, race or culture. SARVAAY plants work with decentralized production model leading to employment and wealth creation in rural areas.

Industry Innovation and Infrastructure

aims at building resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation. SARVAAY jaggery technology has transformed the traditional jaggery making with the blend of science and engineering.

Reduced Inequalities

aims at reducing inequalities and ensuring no one is left behind are integral to achieving the Sustainable Development Goals. SARVAAY jaggery technology creates local credible employment opportunities leading to reduced inequalities

Responsible Consumption and Production

aims at ensuring sustainable consumption and production patterns, which is key to sustain the livelihoods of current and future generations. SARVAAY jaggery technology is an appropriate technology based on philosophy of ‘Small is Beautiful’ promoting resource and energy efficiency, sustainable infrastructure, and green & decent jobs leading to a better quality of life for all.

Our Story

The vison of SARVAAY is to create income generation opportunities in rural areas using local resources and appropriate technology. ‘SARVAAY’ means being connected with everything. We develop technology solutions for the small-scale agro and food processing sector.

Founder story for jaggery technology development

Founder Dr. Vishal Sardeshpande, an IIT Bombay energy engineer with more than two decades of industrial & research experience, hails from a farmer's family located in a small town in central Maharashtra. In the year 2007, just after finishing his doctorate, he visited a jaggery processing plant in central Maharashtra. Despite natural sweeteners with health benefits, he was very upset to see the use of various harmful chemicals (clarifying agents and artificial colour) and the unhygienic process for jaggery manufacturing

...

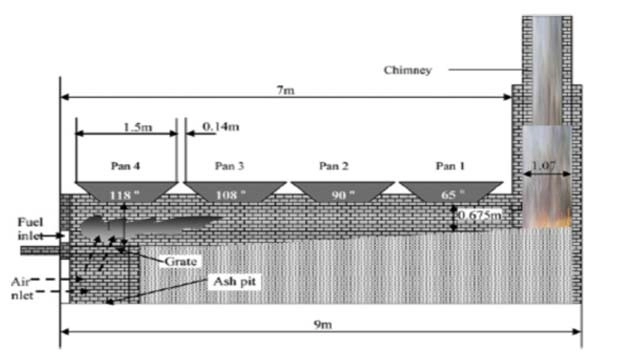

This has challenged engineer and innovator in him to look for better options for hygienic processing. To explore this topic further, he visited jaggery processing plants in various areas and interacted with farmers and manufacturers. The major concerns reported were availability of skilled labor, fuel sufficiency, consistent quality and shelf-life of jaggery. Based on input received from jaggery manufacturers, he has methodically investigated jaggery plant operations and published research articles in international journals and also worked with International research in 2010-14.

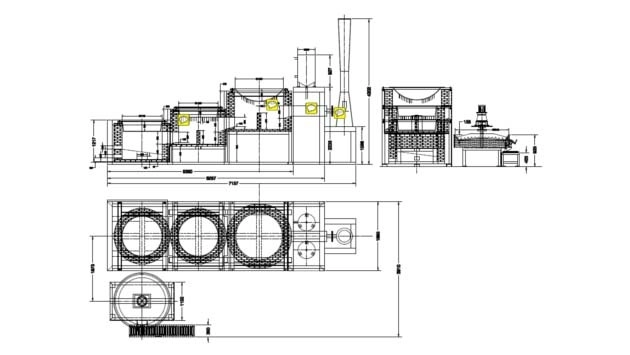

He was not just happy with intellectual investigations and academic research but wanted to find a novel implementable solution for jaggery processing. The founder strongly believes in the “Small is Beautiful” philosophy of E. F. Schumacher for creating resource-efficient, appropriate technologies. This has inspired him to write a patent for a unique small scale jaggery processing plant design with hygienic and resource efficient operation in-year 2011. He worked with two jaggery pilot plant installations in 2011-2016 (while working in corporate).

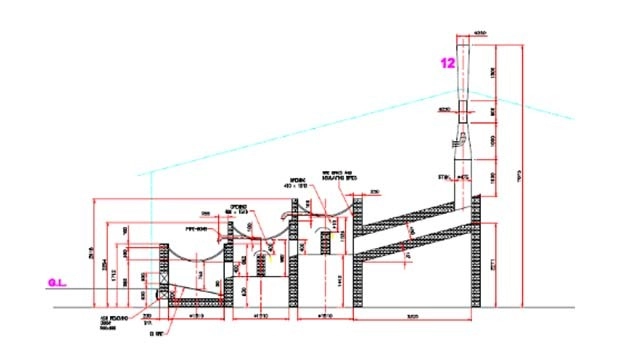

In order to demonstrate his concept to the market, he left the company and started full-time work on a jaggery processing plant from 2016. With the help of a few friends and funds from saving, he designed and manufactured a pilot demonstration plant. The pilot demonstration plant was installed at one of his friend’s facilities at Loni Kalbhor, Pune in Jul-2018. The plant was initially operated for water boiling (instead of sugarcane juice) to establish all the scientific principles for combustion, boiling and heat transfer. As a plant deals with efficient use of resources, the name is coined as ‘Resource Efficient Jaggery Processing (REJP)’ plant. There were considerable efforts on understanding protocols for chemical-free jaggery processing. The use of chemicals is required mainly due to poor process control and empirical operations. The major sources for unhygienic processing are primitive plant layout and rudimentary plant design.

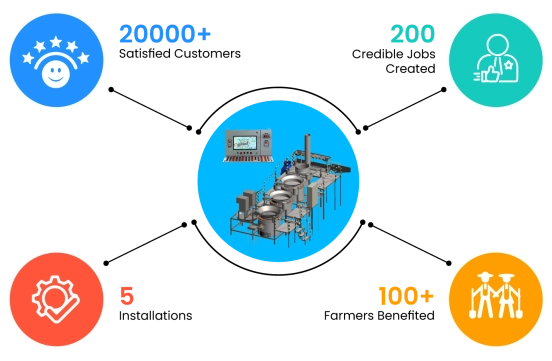

The plant started producing jaggery from Jan-2019 and produced more than 3000 kg of chemical-free jaggery during trail runs till May-2019. The jaggery produced was well received during sampling and test marketing. The founder wanted to understand the market requirement for a small-scale plant. He wrote an article in ‘Agrown’ newspaper for farmers. There was an overwhelming response. He received more than 200 calls expressing the need for small scale technology. As part of the marketing and outreach effort, the founder conducted product promotion workshops in Nov-2019 and received the first commercial order in Dec-2019. With the commercial order, the founder streamlined all the manufacturing drawings and engineering standardization of the plant. The plant was delivered in March-2020, before the founder’s team commissioned the plant Covid-19 strike. The plant was successfully commissioned in Jun-2020, but there was considerable setback for the economy. Despite a setback in the economy, the founder received two plant orders in FY20-21. The founder and cofounder felt a need for a new full-scale demonstration plant. The full-scale operating plant was commissioned at Pirangut, Pune in Jan-2022. This plant is acting as a training, demonstration and confidence-building setup for future customers. The cofounder is involved in the manufacturing and selling of jaggery produced from the new full-scale plant.

Our Founders

Dr. Vishal Sardeshpande

Founder

Dr. Vishal is M. Tech and Ph.D. from Department of Energy Science and Engineering (DESE), IIT Bombay and fellow of Oxford University UK.

He has 25+ years of experience in energy efficiency for industrial and commercial establishments, product development from idea to commercialization and thermal energy system application engineering in formal and informal sectors.

He is adjunct associate professor to CTARA (Centre for Technology Alternatives for Rural Areas), IIT Bombay, doing his teaching and research in the domain of appropriate technology, Product development and MSME in rural areas.

He has been associated with organizations like Forbes Marshall, Thermax, A.T.E. Enterprises, National Dairy Development Board (NDDB), Ministry of New and Renewable Energy (MNRE),Government of India, and IIT Bombay. He has authored more than 21 publications in journals and applied for 8 patents including one for jaggery processing.

Dr. Madhavi Sardeshpande

Co-Founder

Madhavi is Ph.D. Chemical Engineering, IIT Bombay, and M.Chem. Eng., Chemical Engineering, UICT (formally UDCT), and Bachelors of Engineering, Chemical Engineering, from University of Mumbai.

Executive management program IIM Bangalore. She worked as a Young Scientist – SERB Fellow at Chemical Engineering Department, National Chemical Laboratory (NCL), Pune, India. She has 18 years of experience of experimental investigations and computational modeling in the domain of thermal and fluid systems.

Her work encompasses design and development of experimental setup, define experimental protocol, conduct measurement and implement Computational Fluid Dynamics (CFD) model for experimental data.

She has established Solar Thermal Laboratory at NCL, an experimental facility to test various Concentrated Solar Thermal (CST) systems and its integration with process heat applications in cooking, dairy and textile sectors.

Our inspiration

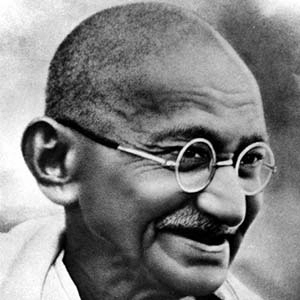

Mahatma Gandhi

I have no doubt in my mind that we add to the national wealth if we help the small-scale industries. I have no doubt also that true Swadeshi consists in encouraging and reviving these home industries. It also provides an outlet for the creative faculties and resourcefulness of the people. It can also usefully employ hundreds of youths in the country who are in need of employment.-“Village Industries” author M. K. Gandhi

E. F. Schumacher

Even bigger machines, entailing even bigger concentrations of economic power and exerting ever greater violence against the environment, do not represent progress: they are a denial of wisdom. Wisdom demands a new orientation of science and technology towards the organic, the gentle, the nonviolent, the elegant and beautiful. – “Small is Beautiful” author E. F. Shumacher

Prof. A. W Date

The large percentage of the population living in rural areas, the prime necessity for prosperous agriculture for self-reliance in food, the decreasing land-man ratio in the wake of alarming population growth, the incapacity of the modern industrial sector to augment employment and the continuously declining purchasing power of the rural poor are some of the parameters which indicate that solutions to basic problems of underdevelopment must be found in the country-side. – ‘Understanding Appropriate Technology’ author Prof. A. W. Date.

Village Industries

CHAPTER 10

GUR AND KHANDSARI

Take the sugar industry. The largest major industry next to the textile is that of the manufacture of sugar. It stands in no need of our assistance. Sugar factories are fast multiplying. Popular agencies have done little to help the growth of this industry. It is indebted for its growth to favourable legislation. And today the industry is so prosperous and expanding that the production of jaggery is becoming a thing of the past. It is admittedly superior to refined sugar in nutritive value. It is this very valuable cottage industry that cries out for your help. This by itself furnishes large scope for research and substantial help. We have to investigate the ways and means of keeping it alive. This is but an illustration of what I mean.

*Harijan (Magazine).